The Ota City Super Factory Prototyping Programme is now open for applications from startups in Southeast Asia

It all starts with an idea.

Existing innovations, from the seemingly mundane to the mind-blowing, were once sketches and concepts brought to life by the power of design and production. To this end, the success of any production process hinges on a reliable manufacturing company.

For many years, China and Taiwan have gone head-to-head in being the go-to manufacturing destination of businesses globally. Key characteristics for manufacturing, which include productivity, quality control, good design, and cost effectiveness, are distinct in the production hubs of these two nations.

Decades ago, a different narrative

In Asia, it hadn’t always been China and Taiwan only.

Back in the 1970s and 1980s, Japan was a powerful contender in the business of manufacturing. However, its importance declined sharply along with the rise of production costs, ageing business owners, dwindling customers, and a rapidly changing technological landscape.

For a long while, it seemed as if the small factories in Japan couldn’t adapt quickly enough to the swiftly evolving trend in manufacturing.

Bouncing back and the rise of the “super factories”

With superior technology still on their side and with the advent of Japanese manufacturing startups, the small factories in Japan are finding a new lease in business life.

Realising the need to have better access to these various factories, the “Super Factory” was born, an organisation of small to medium-sized manufacturers who are world famous for their cutting edge technology in high precision manufacturing and know-how for it. Some of these ‘super factories’ are famous for their technology in manufacturing the parts for unmanned spacecraft and painless syringe needle.

In Ota City, a manufacturing hub is born

Among the cities harnessing the economic potential of super factories is Ota City, the heart manufacturing spot located in Tokyo, Japan. With its close proximity to Haneda Airport, it makes an excellent gateway for startups seeking reputable manufacturing partners for their prototyping needs.

Taking the initiative one step further, the local government of Ota City adapted the “nakama-mawashi” principle in the development of its manufacturing hub. In a nutshell, this means factories with different expertise take each part of a prototyping need to create a one-stop manufacturing facility. Through this method, they are able to meet most manufacturing needs.

At present, the super factories in Ota City excel in seven major manufacturing categories: total engineering, metal, resin, parts, mechanical, electronic, and product design.

Opening the gateway for ASEAN startups: The Ota City Super Factory Prototyping Programme

With the hub in place, the Ota City government is opening up the city’s entryway to the ASEAN market by initiating the Ota City Super Factory Prototyping Programme.

Organised by Leave a Nest and sponsored by the Ota City government, the programme aims to further accelerate the product development of startups so their solution or product will be released to the market sooner, hence solving issues at a quicker pace.

Through this initiative, the local government aims to gain visibility for its manufacturing hub and increase the number of overseas startups working with factories in Ota City. Future plans include becoming a hub for startups, since the city has easy access to Haneda Airport.

The call to network and collaborate with super factory partners in Japan

Now on its second run, the programme is calling for applications from startups all over Southeast Asia who are seeking to accelerate their prototyping by collaborating with the super factories in Ota City.

Startups who take part in this programme could be one step closer to gaining access to the Japanese market and to the network of major firms.

Last year, all 3 startups chosen to move forward in the programme – iVET (Thailand) Co., Ltd., ACeT Innovates Sdn. Bhd., and Red Dot Drone Pte. Ltd. – succeeded in finding their manufacturing partners. For five months, they worked together with their prototyping partners and developed a working prototype or needed equipment.

iVET (Thailand) Co., Ltd., a startup from Thailand, is running an animal hospital and developing technologies for pets (mainly cats and dogs) that will be used by veterinarians when advising treatment. At the programme, they worked with an expert of metal process called SANRIKI CORPORATION to create a sustainable and lightweight wheelchair prototype.

ACeT Innovates Sdn. Bhd., a UPM based startup from Malaysia, aims to be the pioneer in production and manufacturing of enzyme for the Kenaf industry. At the programme, they worked with a total engineering super factory called I・OTA LLC to create an automated device to produce eco-enzyme from locally isolated fungus that will help the retting process of Kenaf to obtain fibre.

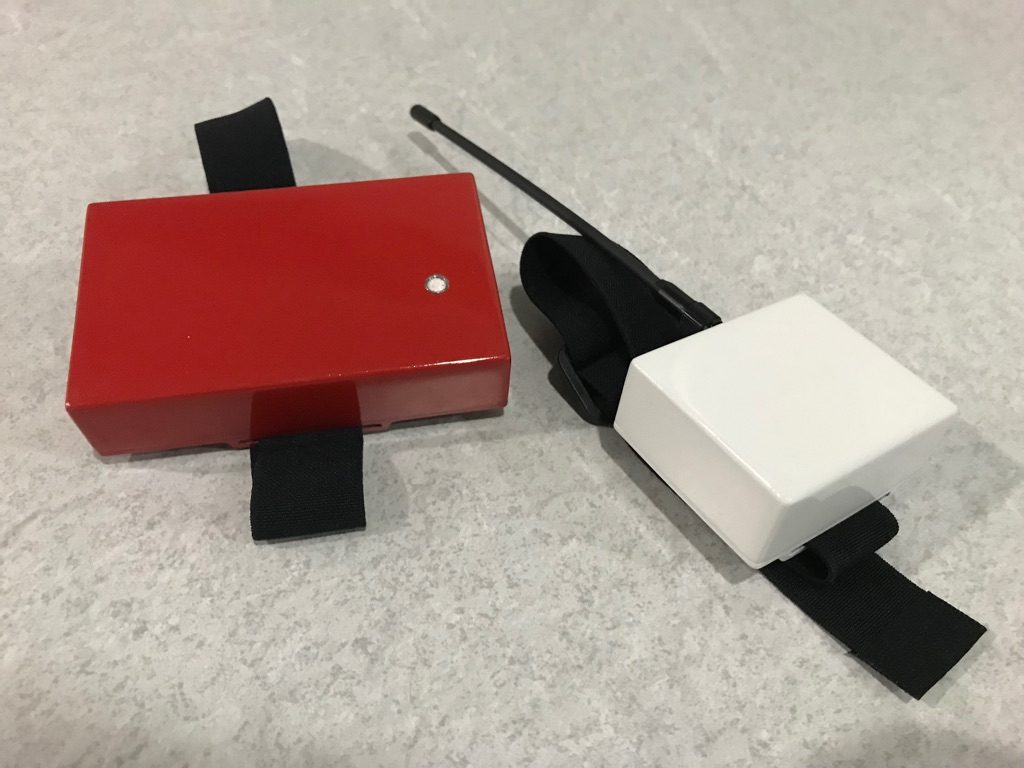

Red Dot Drone Pte. Ltd., a drone startup from Singapore, is focussing on automatic aerial filming technology for sports events. At the programme, they worked with a super factory called Kowa Techno LLC to create a physical GPS device for Drone for sports entertainment.

But the programme doesn’t end when prototyping has succeeded.

Leave a Nest Co., Ltd., the organiser of the programme that has run a series of real-tech seed acceleration programme called TECH PLANTER in Japan and ASEAN regions, also matches the startups with major firms in Japan to further accelerate their businesses.

Why should startups join this programme?

- Startups get a fully funded prototype manufacturing support with the suitable partner factories (Around US$50,000 per project).

- Two round-trip tickets to Japan. The first trip, slated for September this year, is for qualified startups to meet their manufacturing partners. The second trip, scheduled in March 2020, will be for startups to see the completed product and attend the showcase event.

- A coordinator from Leave a Nest will join the qualified team to support their business, including access to a network of major firms in Japan.

Who should join the programme?

Startup companies in Singapore, Malaysia, Thailand, the Philippines, Indonesia, or Vietnam who:

- Need manufacturing support

- Are Interested in teaming up with manufacturers & business partners in Japan

- Have a vision to change the world for a better place through their products or services.

Applications will run until 5 August 2019, and selected startups will be invited to come to Tokyo, Japan in September for the Kick Off event and in March 2020 for the final presentation. For more information, you may download the project description here. Ready to join? Click here to begin your application process.

For inquiries, you may reach Tsuyoshi Inoue or Takumi Jindo of Leave a Nest Co., Ltd. via their email: gpd@lnest.jp

This project is organized by Leave a Nest Co., Ltd., sponsored by Ota City, Tokyo, Japan.

The post How a Japanese initiative backed by local government is accelerating product development in Southeast Asia appeared first on e27.